The Need for Speed

A customer needed a better way to move NOV Ideal rigs on the pad in the lower 48. They had some tough requirements: fast hole-to-hole times, fast rig-up/rig-down times, high accuracy, and minimal pieces to handle. Their drill program would involve setting up a pad in remote areas, quickly drilling multiple holes on the pad, and moving on to the next pad as soon as possible. They needed a system that had as few separate pieces as possible to simplify handling, and they needed to be able to assemble the rig with as little crane assistance as possible. To simplify moves from hole to hole, they needed to move their mud boat with the rig as a single piece, without lifting it with a crane. Lastly, the client was looking for additional height under the rotary table of the rig.

Analysis

The customer's need for fast hole-to-hole moves would require something more sophisticated than a typical manual walking system. While a manual Entro walking system is orders of magnitude faster than many other systems for moving a rig on a pad, the customer needed to improve the efficiency of their rig walking operations. The slowest operation on a manual Entro walking system is adjusting steering because each foot is lifted off of the ground and turned by manually rotating a gear with a ratchet.

Providing a King-pin Walker with power steering would substantially improve the speed of the walking system, but even further improvements in speed could be realized by automating the entire walking process - lift, travel, and steering - so that all inefficiencies could be eliminated from the walking cycle. The customer also required a walking system that disassembled down into as few separate pieces as possible to simplify their logistics, and also didn't want any major structural modifications to their current substructure. These two requirements both pointed towards a Pony-Sub solution, where each box on the rig substructure is placed on top of a full-length module that carries two complete walking feet.

By placing two walking foot assemblies in one box, the number of crane picks required to rig-up is cut in half. And, by putting the entire walking system and supporting structure in a single module, no significant structural modification to the existing rig was required.

The customer needed to walk their mud boat with the rig, without using a crane. By taking advantage of the rig walking system, a simple jacking system could be used to lift the mud boat straight up to allow the rig to walk underneath it, simplifying the rig-up procedure.

The Solution

Controls

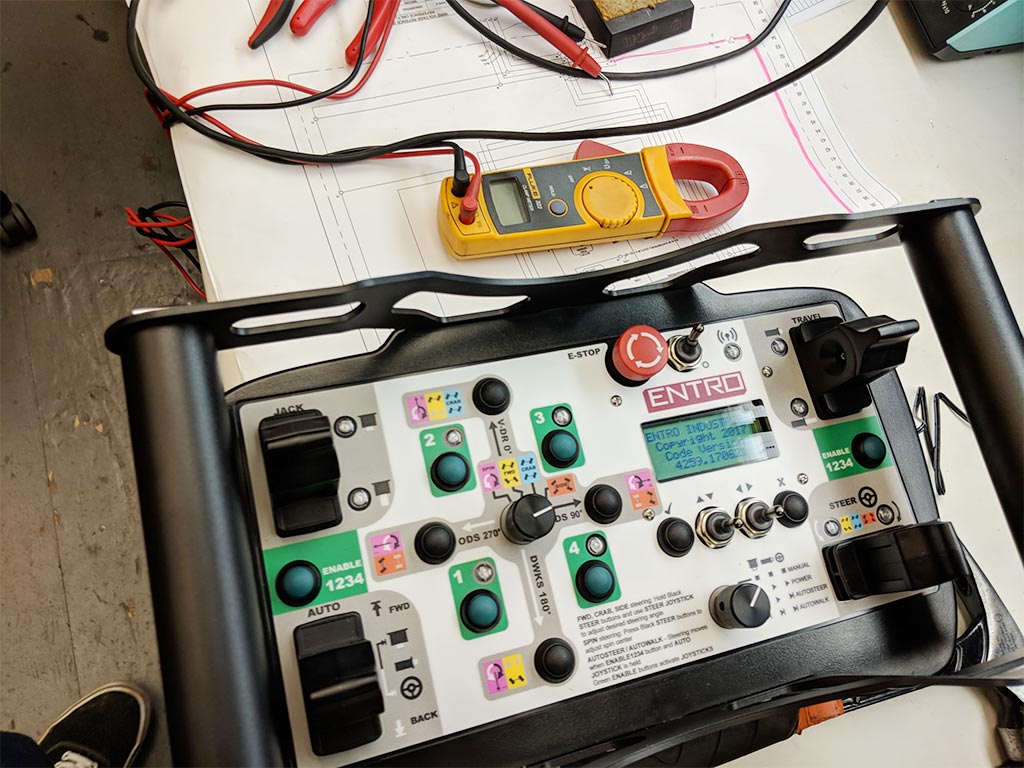

To meet the customer's requirement for quick moves, Entro Industries developed patented controls technologies to allow faster rig moves. The AutoWalk and AutoLift systems were developed to allow an operator to walk a rig like a remote-control car; an operator would pick a direction of travel and the system would automate the entire walking cycle. The result was a walking cycle that could complete rig moves in a fraction of the time of manual systems.

Structure

Entro provided the walking system in a low-profile Pony Sub package that integrated wire harnesses, hydraulics, and machinery into a single load. Each pony sub was a single truck load and could be picked up with a crane. The customer's substructure sits on top of the Pony Sub boxes and pins in place with a kit provided by Entro.

Additional Equipment

To raise the customer's mud boat onto their substructure without a crane, a special jacking skid was provided that would lift the mud boat above the rig and allow the rig to walk underneath it.

Uniquely suited to rigs where conventional walking feet do not perform well. The patented design allows a large sized foot to be placed in confined areas while still allowing the rig to move in ANY DIRECTION. MORE

Entro builds control consoles for all of our machinery of every shape and size. Our control consoles can vary widely, from manual handle control only, automated motions based on sensor data. Wireless remote controllers are a popular added feature due to the increased safety, flexibility, and visibility. MORE

Designed to efficiently mobilize land-based, box-on-box drilling rigs for hole-to-hole moves. The Entro system fits large walking feet into existing sub designs and still maintains the ability to move in ANY DIRECTION. MORE

The optional Autowalk and Autolift systems allows a single operator to steer all of the walking feet with a wireless remote control. This eliminates the need for personnel to manually steer the walking feet, improving safety and efficiency. MORE